Hardware Buying Guide

Choose Top-Quality Rigging Hardware and Overhead Lifting Equipment

Hardware Buying Guide

The quality of the materials you use has a strong impact on the outcome of your project. Regardless of the size of your budget, it is important that you use high-quality industrial appliance hardware and equipment, especially for lifting applications.

Using cheap or poor quality equipment is extremely dangerous and even puts the safety of your workers at risk. Many of the most common construction worker injuries and deaths are directly related to equipment problems.

According to a recent crane safety survey cranes, 37% of accidents were caused by a swinging load or an unstable load falling on a person. Twenty-seven percent of these injuries were caused by poor rigging practices, which caused a load to fall or come off the sling.

The use of low-quality lifting appliances and equipment can increase the risk of malfunctions and put the health and safety of all equipment at risk.

Choosing reliable industrial hardware and rigging equipment will greatly improve the outcome of your product. Higher quality tools will last longer, perform better, and support a more efficient process.

But finding and purchasing the best rigging and lifting hardware equipment is a huge task. Ultimately, it all comes down to finding a reliable rigging equipment supplier to purchase industrial hardware from.

However, finding an industrial hardware supplier company can be more difficult than you imagine. There are many options and each dealer offers many different brands, sizes and types of rigging equipment. How can you be sure you are getting the best deal and choosing the best products?

In this guide, we’ll break down all the different types and styles of rigging equipment and cover all the information you need to make an informed purchasing decision.

Let us begin.

Select high-quality rigging hardware for your business

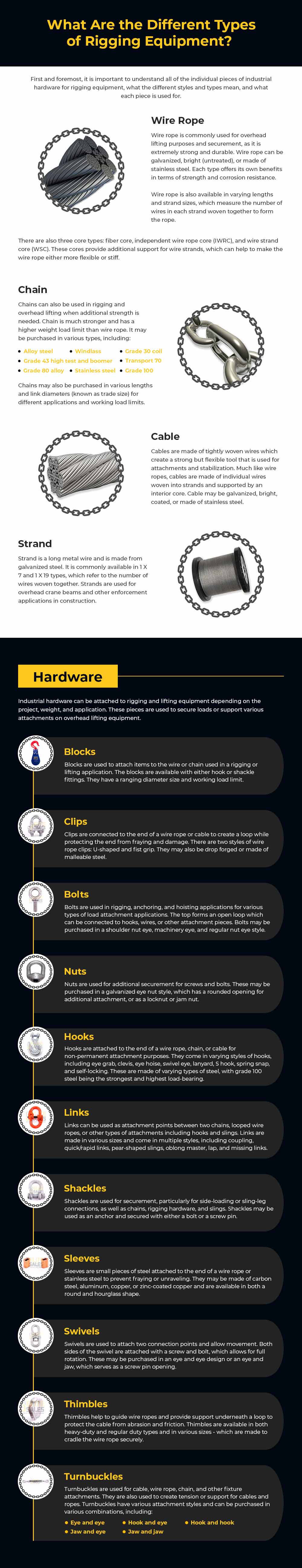

WHAT ARE THE DIFFERENT TYPES OF RIGGING EQUIPMENT?

Firstly, it is important to understand all the individual industrial hardware pieces for rigging equipment, what the different styles and types mean, and what they are used for. use each piece.

WHAT ARE THE MOST IMPORTANT FACTORS WHEN CHOOSING RIGGING EQUIPMENT?

Load Limit

First, you will need to calculate the load weight that will be used with the hardware to ensure it is within the load limit. The weight load limit (WLL) is the absolute maximum weight the equipment is designed to hold without breaking or bending.

It’s usually best to give yourself some wiggle room here. Purchase hardware that is rated for a load limit greater than the load it will be used for. This will ensure the highest level of security.

The Environment

The workplace environment can also affect the type of hardware materials you will need to use.

Some metals will rust if exposed to rain or moisture. So, if you are using equipment that will be near a body of water or might get rained on, you will want to use stainless steel hardware, which is naturally resistant to rust, or galvanized finishes.

Extreme temperatures can also affect equipment .

Low temperatures can cause hard metals like steel to become more brittle. It will also cause materials made of nylon to become rigid, which can reduce their load-bearing capacity.

On the other hand, extreme heat can also damage hardware, especially if left in direct sunlight for long periods. Some hardware pieces are specifically designed with high heat resistance to prevent this from happening.

Weather conditions can also cause industrial hardware to wear out faster. Heavy snow, rain, wind or hail can dent, scratch or wear materials. It is important to keep this in mind when choosing hardware. If you are in an area that experiences more extreme weather conditions, then you should purchase rigging equipment that is sturdier or has a protective coating.

Maintenance

Most rigging accessories and equipment are made of steel, which is quite strong in itself. However, the finish can affect its durability. Shiny or unfinished metal is more prone to scratches, dents, corrosion and rust, while galvanized or stainless steel is more durable.

Some industrial hardware materials will simply be more durable than others, but this durability often comes at a higher price. This is a trade-off you should choose between when purchasing rigging equipment.

Performing regular inspections can help extend the life of rigging equipment, especially for materials such as cables and chains. These can be easily repaired if they start to wear out. Proper maintenance will also help increase the durability of the equipment.

OSHA Compliance

OSHA and ASME (American Society of Mechanical Engineers) have their own set of standards for rigging equipment to ensure that the machinery used is safe and up to code. For overhead lifting equipment, materials must be tested for accurate weight load limits and have specific visible markings for identification.

Any rigging equipment you purchase should be certified to OSHA approved test tests . OSHA also requires that aerial lifting equipment be inspected before each use and any defective hardware must be removed or repaired immediately.

There are also specific ASME standard classifications. for specific teams.

For example:

- Slings must meet ASME B30.9 standards

- Hardware, including shackles, sling hooks and turnbuckles, must meet ASME B30.26 standards

- Overhead cranes

Budget

Of course, budget is one of the biggest deciding factors when it comes to purchasing aerial rigging equipment. But while it can be quite tempting to buy industrial hardware that costs less, this is not always the most ideal option. It is always best to go with the highest quality rigging equipment that is within your budget price range.

Poor quality lifting and rigging equipment can end up being more expensive than purchasing better quality hardware. Cheaper equipment generally needs to be replaced or repaired more frequently than more expensive, high-quality parts.

This not only costs extra money, but wastes a lot of time when production has to stop to change hardware. In fact, unplanned equipment downtime is estimated to cost $260,000 per hour with lost production time and costs associated with equipment replacement. This wasted time and additional expense can be avoided by sticking with higher quality rigging equipment in the first place.

WHAT TO LOOK FOR IN A QUALITY SUPPLIER OF ASSEMBLY EQUIPMENT

To ensure that you are purchasing only the best quality of rigging equipment, you need to find an industrial hardware supplier that is reliable and trustworthy. You also need to know how to navigate the research process. This will help you narrow down your options and find the dealer who will provide you with the best equipment.

This includes:

- Research reviews

- Comparison of offers and product ratings

- Determine actual costs (shipping options, shipping rates)

- Location and convenience (they offer local delivery or pickup)

- Customer service availability

- Return Policy

Here at Elite Sales, we know how important it is for people to find an industrial hardware supplier. You want to be sure that you can trust your equipment and get it at a fair price. That’s why we have an extremely thorough and comprehensive selection process for all suppliers of the equipment we sell. This includes (but is not limited to):

- Personal visits to factories annually to evaluate them and ensure they are producing correct specifications and adopting the newest technology.

- We have strict measures to remove a factory from our approved suppliers if they have repeated quality problems.

- Ensure our suppliers’ factories are ISO and API approved.

- People from ISO and API visit factories regularly to ensure that they continue to meet the standards of those individual specifications.

- At random, we will send independent auditors to factories to act on our behalf and review all merchandise they are producing. This is to ensure they meet the correct specifications before shipping to us.

At the end of the day, we do not sell ANY equipment unless the supplier has been thoroughly vetted. After all, your lives and those of your workers are in your hands.

WHAT TO LOOK FOR IN A QUALITY SUPPLIER OF ASSEMBLY EQUIPMENT

It’s essential to contact knowledgeable hardware retailers to point you in the right direction. If a supplier doesn’t have someone available to guide you to the right products or answer your questions, it’s a good sign to stay away.

You want to buy from companies with people well trained in rigging equipment. This is to ensure that you are getting the right hardware for the task at hand.

At Elite Sales, we believe in transparency when it comes to the products we offer and the services we provide. Our customer service team is just a call away. We are available to answer any questions you may have about our company, products and pricing structures.

LET'S STAY IN TOUCH

There is no reason why you should not purchase the best quality industrial lifting equipment and rigging for your project. The quality of the hardware you use will influence the outcome of your work, so you should only use the best of the best.

If you are looking for affordable, high-quality industrial hardware and rigging equipment supplies, look no further than Elite Sales . We are proud to be a premier industrial rigging equipment provider serving Miami & amp; Tampa, FL, Houston, TX and Indiana areas.

Our team has over 100 years of combined industry experience. We can answer any questions you have about our products.

For more information about the products we offer, our shipping services, or to speak with one of our industry experts, contact Elite Sales today.