General Information About Wire Rope

Wire Rope

STRAND PATTERNS: They refer to different types of arrangements of wires and their diameters within a strand. Common strand patterns are Filler Wire, Seale, Warrington and combinations thereof.

LAY: Indicates how the wires have been laid to form strands and how the strands have been laid around the core. A right regular lay rope (RRL; the most common) has its strands laid right on the rope, similar to threading a right-hand threaded bolt. Regular means that the direction of the wire lay in the strand is opposite to the direction of the strand lay in the rope. (The wires in regular lay rope appear to be in line with the axis of the rope.)

CAUTION: When combining separate ropes in a single line application always use ropes of the same lay pattern. Different lays can increase rotation at connection points decreasing rope efficiency.

PREFORMING: A manufacturing process wherein the strands and their wires are permanently formed, during fabrication, the helical shape that they will ultimately assume in the finished wire rope. Proper preforming prevents the strand and wire from unlaying during normal use. The vast majority of wire ripe sold today is preformed.

FINISH: Wire rope is either sold as “bright” (or “black”), meaning uncoated, or galvanized for better corrosion resistance. “Drawn Galvanized” wire has the same strength as bright wire, but wire, “galvanized at finished size” is usually 10% lower in strength. Plastic coated wire rope is also available, usually galvanized or stainless steel cable. The most common plastic coverings are vinyl or nylon in either clear or white, although other materials and colors are available. These coating do not add strength to the wire rope itself.

LUBRICATION: During fabrication, wire ropes receive lubrication. The kind and amount depends on the rope’s size, type a use, if known. This in-process treatment will provide the finished wire rope with ample protection for a reasonable time if it is stored under proper conditions. But, when the wire rope is put into service, the initial lubrication will normally be less than needed for the full useful life of the wire rope. Because of this, periodic applications of a suitable wire rope lubricant are necessary.

ORDERING WIRE ROPE: Construction, lay, core, finish and other factors mentioned above impart greatly differing characteristics to different wire ropes. They must be understood and considered when selecting wire rope. There is no perfect wire rope for all applications; usually some less desirable properties are traded off for other, more desirable one. Refer to the Wire Rope Users Manual by the Wire Rope Technical Board for a better understanding of wire rope properties and consult professional help when in doubt.

Lacking a complete description of the wire rope desired, a supplier can make several assumptions:

- If direction and type of lay are omitted from the rope description, it is assumed to be right regular lay (RRL).

- If finish is omitted, this will be presumed to mean ungalvanized, “bright” finish.

- If no mention is made with reference to preforming, preformed wire rope will be supplied.

- If a supplier receives an order for 6 x 19 wire rope he may assume this to be a class reference and is, therefore, legally identified in furnishing any construction within this category.

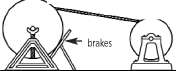

Rereeling Wire Rope

Correct

Wrong

Wrong

Cutting & Seizing Wire Rope

Breaking In New Wire Rope

Wire Rope Efficiency

Wire rope will develop 100% efficiency, that is, break at or above minimum acceptance strength (not less than 2 1/2% below nominal breaking strength ) under controlled laboratory conditions.

Once fittings such as sleeves, clips, sockets, etc. are attached and/or the wire rope passes over a curved surface such as sheaves, pins, etc. its strength is decreased. In the case of wire rope passing over a curved surface this decrease in strength depends on the severity of the bend. In the case wire rope fitting, the decrease in wire rope strength will depend on the type of fittings used. The wire rope efficiency usually ranges for 70% – 100%. For more detailed information consult the strength efficiency of wire rope graph on page ## in the ________ section. Note, that hand spliced wire rope, while not using any fittings, has less efficiency than properly flemished and swaged wire rope. There are other factors, depending on the application of wire rope, that can cause a decrease in nominal wire rope strength. They must be considered when choosing a design factor. Refer to the Wire Rope Users Manual and/or other qualified sources for details.