The Three Basic Wire Rope Components

Wire Rope, Strands and Core

Working Load Limit (WLL)

Wire ropes are perhaps the most widely used rigging and lifting hardware. Wire ropes were designed to help extract ores from mines. However, these heavy-duty cables quickly found use across industries thanks to their meticulously designed wire rope components.

Today, many industries such as construction, automotive, aerospace, manufacturing, marine, military, energy, chemicals, warehousing, and railway use wire ropes. You can use wire ropes for hoisting, positioning, lifting, rigging, and moving heavy loads.

So, what makes wire ropes so unique?

Wire ropes can:

- Be fabricated to minimize torsion

- Withstand high temperatures

- Carry heavy loads

- Be suspended in water or chemicals for long periods

- Suffer continuous vibrations or ad hoc shocks

Wire ropes consist of three basic components that render them the ability to perform under extreme conditions. Although few, the wire rope components vary in complexity and configuration. These variations allow you to create wire ropes with varying strengths.

If you are going to use wire ropes, you will need to understand how these wire rope components work. That, in turn, will help you choose the wire ropes that best fit your rigging and lifting needs.

Let’s understand what are the wire rope components and how they function.

Wire Rope Components

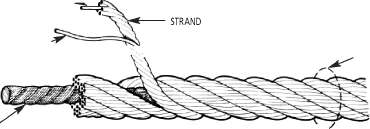

The Three Basic Parts of a Wire

- Wires

- Strands, formed by wires, are laid helically around a core.

- Core, or center.

MATERIAL: Steel grades in wide use today are IPS (improved plow steel) or EIPS (extra improved plow steel), sometimes also referred to as XIPS, XIP, EIP. Stainless steel grades 302/304 and 316 are most common.

CORE: Its function is to provide proper support for the strands under normal conditions. Three types of core (or center) are commonly used.

- Fiber Core (F.C.), usually polypropylene, sometimes hemp (H.C.) and sisal.

- Independent Wire Rope Core (IWRC)

- Wire Strand Core (WSC)

IWRC and WSC are sometimes referred to as steel wire core or steel center.

Design factor (sometimes called safety factor)

The Three Basic Parts of a Wire

- Wires

- Strands, formed by wires, are laid helically around a core.

- Core, or center.

MATERIAL: Steel grades in wide use today are IPS (improved plow steel) or EIPS (extra improved plow steel), sometimes also referred to as XIPS, XIP, EIP. Stainless steel grades 302/304 and 316 are most common.

CORE: Its function is to provide proper support for the strands under normal conditions. Three types of core (or center) are commonly used.

- Fiber Core (F.C.), usually polypropylene, sometimes hemp (H.C.) and sisal.

- Independent Wire Rope Core (IWRC)

- Wire Strand Core (WSC)

IWRC and WSC are sometimes referred to as steel wire core or steel center.

Wire Rope Constructions

CONSTRUCTIONS: Are expressed in numbers of strands x number of wires. 6 x 25 indicates that the wire rope consists of 6 strands, which in turn have 25 individual wires.

Constructions are grouped into classes:

- 6×7 Class: Containing 6 strands that are made up of 3 through 14 wires, of which no more than 9 are outside wires.

- 6×19 Class: Containing 6 strands that are made up of 15 through 26 wires, of which no more than 12 are outside wires.

- 6 x 37 Class: Containing 6 strands that are made up of 27 through 49 wires, of which no more than 18 are outside wires.

- 8×19 Class: Containing 8 strands that are made up of 15 through 26 wires, of which no more than 12 are outside wires.

- 19×7 Class: Containing 19 strands, each of which is made up of 7 wires.

- 8×19 and 19×7 class have wire rope specifications that have rotation-resistant properties, excluding elevator ropes.

The constructions listed above are just some of the more popular constructions. Click here to see what constructions we have available.

Other Common Constructions:

7 x 7,7 x 19: Galvanized cable. Sometimes referred to as aircraft cable but not intended for aircraft use. 1×7,1×19: Strand 7x7x7, 7x7x19: Cable Laid

Many others exist, some for highly specialized applications only.

Note that any class denotes the nominal number of wires in each strand. The actual number of wires may be different. For example: 6×37 class wire most commonly may consist of 36 wires, or 31, or 41.

Contact a Reliable Wire Rope Wholesaler

Due to different wire rope components configurations, wire ropes come in different strengths, specifications, and materials. Choosing the one that best fits your needs isn’t going to be an uphill task, especially if you are a novice.

In other words, you are going to need a reliable, experienced wire rope supplier on your side. Your supplier can help you find the wire ropes best suited for your rigging and lifting needs.

But that’s not the only benefit of working with a reliable wire rope wholesaler.

Other advantages include:

- Purchase only high-quality and reliable wire ropes backed by warranties, among other hardware.

- Get easy access to future upgrades, including upcoming technologies in the rigging and lifting industry.

- Ensure faster incident resolution should there be any disputes.

- Get package deals and discounts on almost all your purchases.

- Ensure last-minute order fulfillment in case of emergency.

If you are looking for all these benefits, you can’t find a better wire rope supplier than Elite Sales. Your wire rope supply is in safe hands thanks to three strategically located warehouses, an inventory worth $20 million, and over 100 years of combined industry experience. That’s what Elite Sales bring to the table.

We also supply other rigging and lifting hardware. Whether a small or a large business, we are here to help you.

Get in touch with us to know how we can help.