Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

At Elite Sales, we get a lot of questions regarding overhead lifting equipment. But as a wire rope distributor, explaining safety factors is one of the most important topics to discuss.

So, let’s break down what the wire rope safety factor is and what it means for overhead lifting, rigging, and construction purposes.

Safety Factor Meaning

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

Some of these factors that can impact the strength of the wire rope include:

- Speed of operation

- Rope attachments

- Wind velocity and weather conditions

- Acceleration and deceleration

- Length of the rope

- Uneven loading

- Shock loading (unexpected drops)

To account for these factors and ensure that the load does not approach the MBL, it is wise to choose a wire rope with a good safety factor ratio.

Safe Working Load

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The way to determine the SWL is by squaring the diameter of the rope and multiplying it by 8 kgs. Thankfully, most wire rope distributors will present this calculation for you.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

Margin of Safety

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there are over 70 fatalities due to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

The margin of safety (also referred to as the factor of safety) measures the ultimate load or stress divided by the allowable stress. This helps to account for the applied tensile forces and stress that could be applied to the rope, causing it to inch closer to the breaking strength limit.

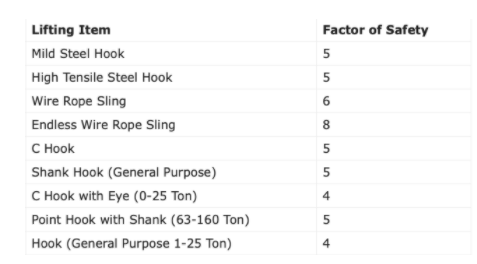

The factor of safety or margin of safety can be calculated for other overhead lifting equipment as well, including hooks, slings, chains, and belts.

Proof Test

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time. OSHA requires that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

Conclusion

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of these wire rope safety factors serve an important purpose.

If you have any further questions regarding wire rope safety factors, please reach out to us at Elite Sales.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.